Bridge Re-Glue

The Crazy Maple back !

BTW: That's Her Sister in the background

same flinch of ( raw wood ) maple, same sitka top wood.

A 12 String Guitar that actually plays in tune ??!!??

Oh Ya ... have a listen ...

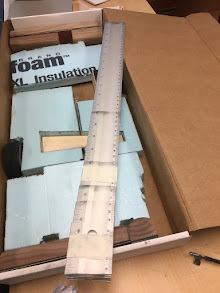

Ready for tapered end splice ...

Another flawless dovetail .....

Dovetail / spalted maple rosette /

soundport / cedar top

BTW: That's a left handed cutaway in the background

Neil finished up the compensated nut

on his American Strat.

Rick re-glued the the 12-String guitar bridge.

Ryan, laying out the compensated nut

for his 8-string ... we'll finish it up next class.

Guitar Repair and Design Courses

Looking for an intellectual, tactile and

conceptual challenge ?

Join us on Patreon , for an exercise

in Design Studies, Analysis,

Trouble-shooting, Problem-Solving,

Geometry, Engineering, History

and more ....

Check out this 60's era',

Trini Lopez copy

Kids in a candy shop ;^ ) !

My Patreon subscribers are happy

to spend the money that they

would have spent anyway ....

learning to setup their instruments ....

the only difference is ....

Now they are getting a front row seat

in my Luthier's repair shop ....

Acquiring a truck load of

Guitar-related knowledge ....

Michael's Roster ....

All of theses guys had covered, or

exceeded, the price of administration

by their 4th class;

by saving the money they would have spent on

Guitar Setups and calibration ;^ ).

Increasingly more and more students, are signing up

on my Patreon

channel, to learn precisely what is involved, in a professional

guitar setup, and to have a clear understanding why

Guitarists are willing to pay a professional price

for a professional job.

BTW: 3 of the setups that I did in my own shop

this past week, were brand new guitars that came with a

"free setup " from the place of purchase.

All 3 of those customers

were not interested in a free setup.

There were HAPPY to pay for a professional setup;

knowing that their guitars will be absolutely

PERFECT when the job is done ;^ ) !

Many of these students have already

" tooled up "

and continue to do this type of work to

generate a part time or full time income.

..... we've worked on Epi 330 /

Left handed Les Paul / a Classical

Precision Bass / Fender Strat

a couple of Seagull acoustics /

7 string Ibanez /

and more ....

300 + Videos posted so far

on Patreon

plenty more to come ...

stay tuned ...

I am just ramping up ;^ )

For anyone old enough to

remember these ....

Fender's answer to the Gibson ES-335'

I just barely had enough "Real Estate" ( below )

on the "saddle travel" to squeak out the intonation.

The compensated nut was the final touch ....

It is now 100% Perfectly in tune .

This is now locked and loaded

... ready for some rippin' guitar licks !

Customer's response, after the ultra-tweak ;^ )

I plugged her in when I got home and Holy S**t!!!!!!

Now that's a damn fine guitar!!!

It's totally changed the feel!!

Thank you for your Mastery Michael!

Terry

The Fender Starcaster ( above) ,

was originally introduced

in the late 70's ( 1977 / 78 ).

Warren ... moving right along with his

Parlour Nylon string soundboard bracing !

Jordan will be gluing up all of his

Steel String Parlour braces next class

Rob has the dovetail fitted and is now moving on

to the headstock overlay / binding and fingerboard.

This group of Guitar Enthusiasts

"dug right in" on the first night ( Monday )

of the 2014 Fall GRAD Session

Guitar Repair and Design

#guitarrepaircourses